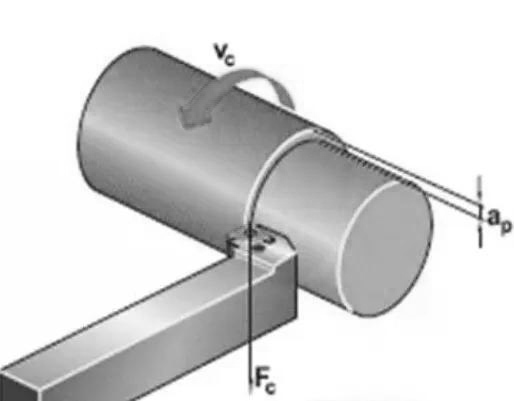

As we all know, in turning processing, the three elements of cutting are cutting speed, feed rate and cutting depth.

Regarding the feed rate and cutting depth, I think everyone can correctly grasp it. In this article, we will talk about what is cutting speed .

Depth of cut (ap) is the single-side cutting amount of the tool in the radial direction of the workpiece during turning. For example, if we turn a part, if we want to turn from 90mm to 86mm, then the depth of cut is 2mm.

Feed (f), according to turning is a process of single-edge cutting of a rotating part, so the feed is the displacement of the tool in the direction of the axis of the workpiece for each revolution of the part.

As for the third cutting element, many people have different understandings. someone likes to call this cutting element as "cutting speed". But in fact, to make it clear to everyone, we must pay attention to the third cutting element, it is the linear velocity (Vc), not the rotational speed (n).

Why not using "cutting speed" ? Because in the expression of speed, it is difficult for us to intuitively understand whether the speed we use in turning is reasonable.

For example, when turning a workpiece, the speed is 100 rpm. If we put this 100 rpm on a part with a very small diameter, then the relative speed of the tool and the workpiece is very low, then may be causing cutting problems in the tool,due to the cutting speed is too low. Conversely, if the diameter of the part is relatively large, then the cutting linear speed of the tool in actual processing is too high for this 100 rpm, then the problem of the use of the tool will also occur.

So, we must emphasize here that the three elements of turning refer to linear speed, not rotational speed.

Dalian Indus Machinery Technology Co.,Ltd

-www.indmt.com