As a super-hard tool material, cubic boron nitride (CBN) tools have been widely used in high-speed cutting of high-hardness and difficult-to-machine materials. They can replace grinding by turning and change the inefficient process of grinding high-hardness workpiece materials with

a grinding wheel. , Improve the processing efficiency and processing quality.

CBN tools can be used to cut cast iron (gray cast iron, ductile iron, high chromium cast iron, alloy wear-resistant cast iron, etc.), hardened steel (bearing steel, die steel, etc.), high-temperature alloys, high-speed steel and other materials. The tool is preferred.

---Typical applications of integral CBN tools---

1. Processing cast iron materials:

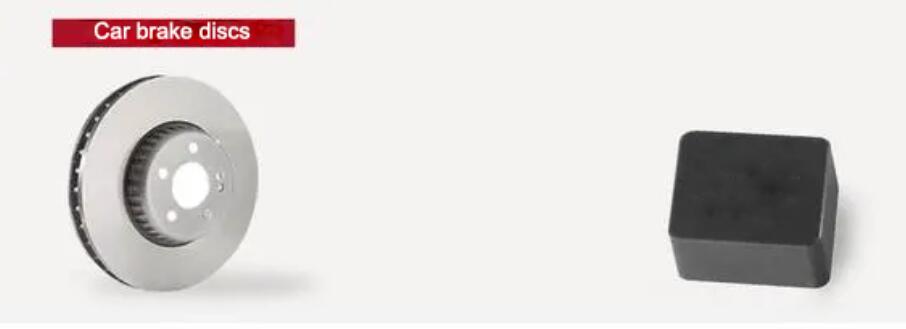

1. Turning car brake discs

The material of the brake disc is generally gray cast iron (HT200~300), and some alloying elements (such as Cr, etc.) are added to improve the performance of the casting. In the past, coated carbide cutters and ceramic cutters were commonly used for brake disc processing,

and currently, the whole CBN cutters are basically used.Compared with the original coated carbide inserts, the tool durability is increased by 5 times, and the processing efficiency is also increased by more than 2 times.

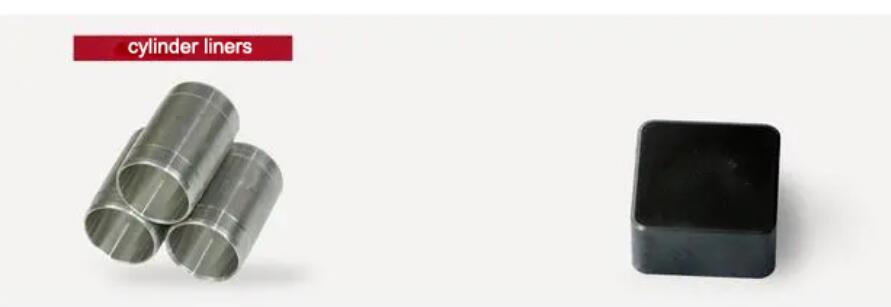

2. Machining cylinder liners

The outer circle of the cylinder liner is processed, the material is boron cast iron, the hardness is HB220~240, and the integral CBN cutter is used for long-distance continuous finishing. The cutting parameters are: Vc=300~500m/min, ap=0.5mm, F=0.25~0.35mm/ r. The tool durability is 6 times that of the original coated carbide tool, which solves the problem of not durable and frequent tool change and improves production efficiency.

3. Machining the engine block

Use integral sintered CBN milling cutter to mill the automobile engine cylinder. The material is gray cast iron, the hardness is HB180~220,

and the cutting parameters are: Vc=800~1000m/min, ap=2~3mm, Fz=0.1~0.15mm. Compared with the original coated carbide inserts,

the durability of CBN inserts is 8 times, and the processing efficiency is more than 4 times.

2. Processing hardened steel materials:

1. Machining slewing bearing

The inner circle of the slewing bearing raceway, the material is 42CrMo, the hardness is HRC58~62, it is turned by the integral CBN cutter, the cutting parameters are: Vc=120~160m/min, ap=0.15~0.35mm, F=0.1~0.2mm/r . The durability of CBN cutting tools is more than twice that of the original ceramic cutting tools, and the processing efficiency is 2.5 times that of ceramic cutting tools.

-Typical applications of welding CBN tools-

1. Processing cast iron materials:

1. Processing flywheel

The material of the flywheel is mostly gray cast iron (HT200~250). If a cemented carbide tool is used, the tool will be changed frequently because the tool is not wear-resistant and the surface finish does not meet the requirements. Adopting Bot's integral welding CBN cutter, the cutting parameters are: Vc=500~700m/min, ap=0.3~0.5mm, F=0.25mm/r. Compared with the original cemented carbide tools,

the service life is increased by 5 times, and the processing efficiency is increased by more than 2 times.

2. Processing hardened steel materials:

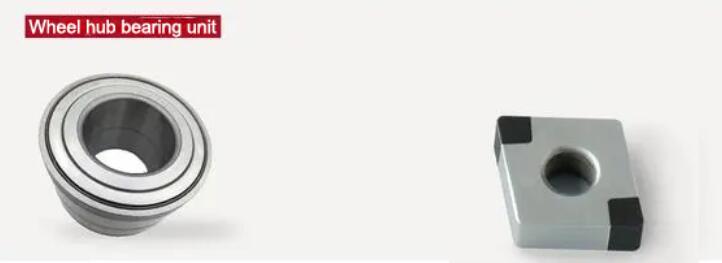

1. Processing wheel hub bearing unit

Turning automobile wheel bearing unit with integral welded CBN cutters, hardness is HRC58~62, cutting parameters are: Vc=120~180m/min, ap=0.1~0.3mm, F=0.15mm/r. Compared with the original coated carbide inserts, the processing efficiency has been increased by 10 times,

and the overall tool cost has been reduced by more than 50%.

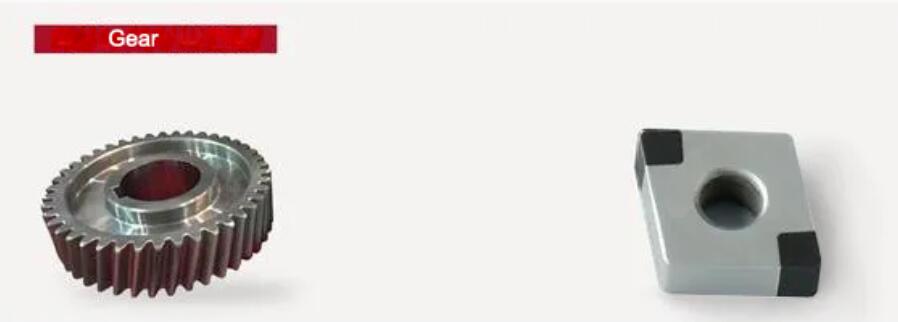

2. Machining the inner hole of the gear

Use integrally welded CBN cutter to continuously finish the inner hole of the gear. The material is 20CrMnTi, the hardness is HRC58~62,

and the cutting parameters are: Vc=120~160m/min, ap=0.15~0.3mm, F=0.05~0.15mm/r. Compared with the original cemented carbide inserts, the service life is increased by 6 times, and it can be realized by turning to replace grinding, which improves the processing efficiency.

Dalian Indus Machinery Technology Co.,Ltd

-www.indmt.com